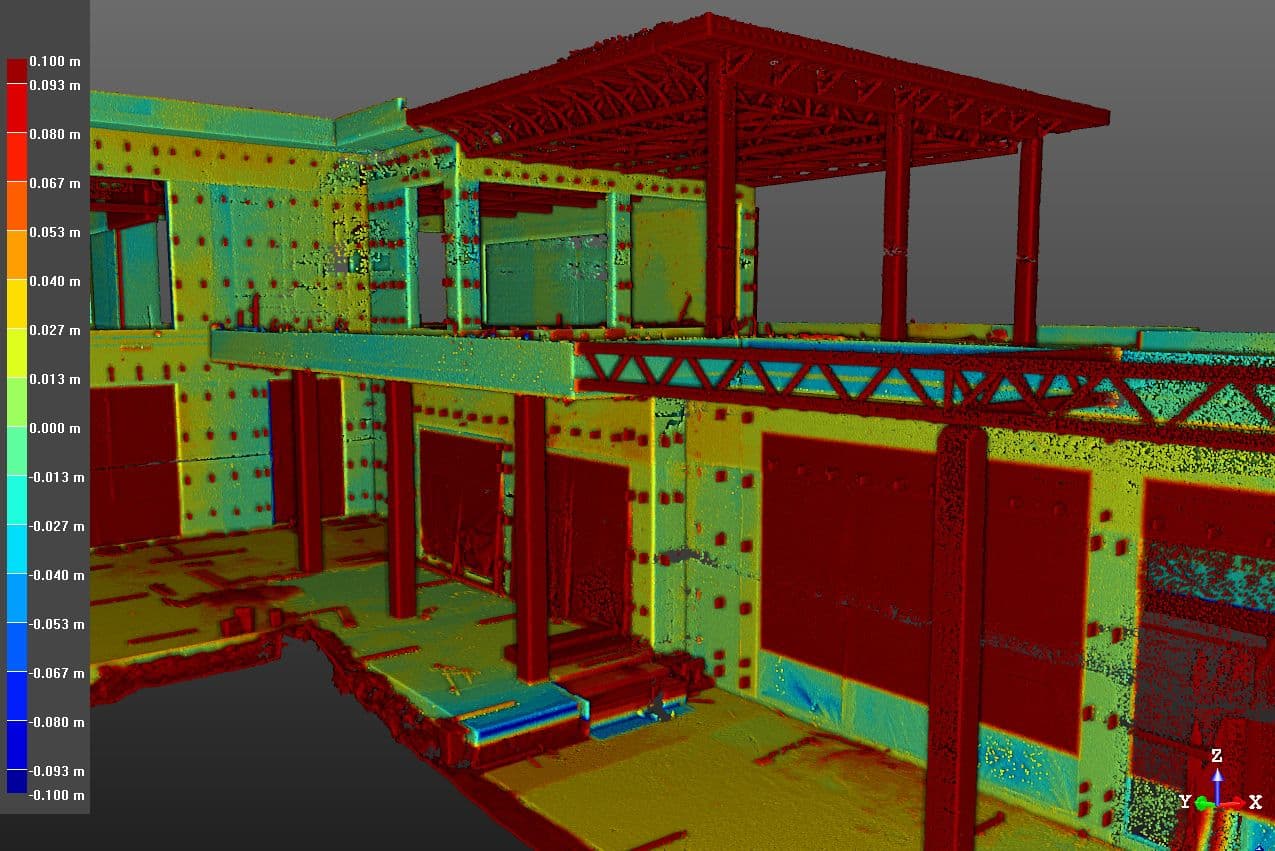

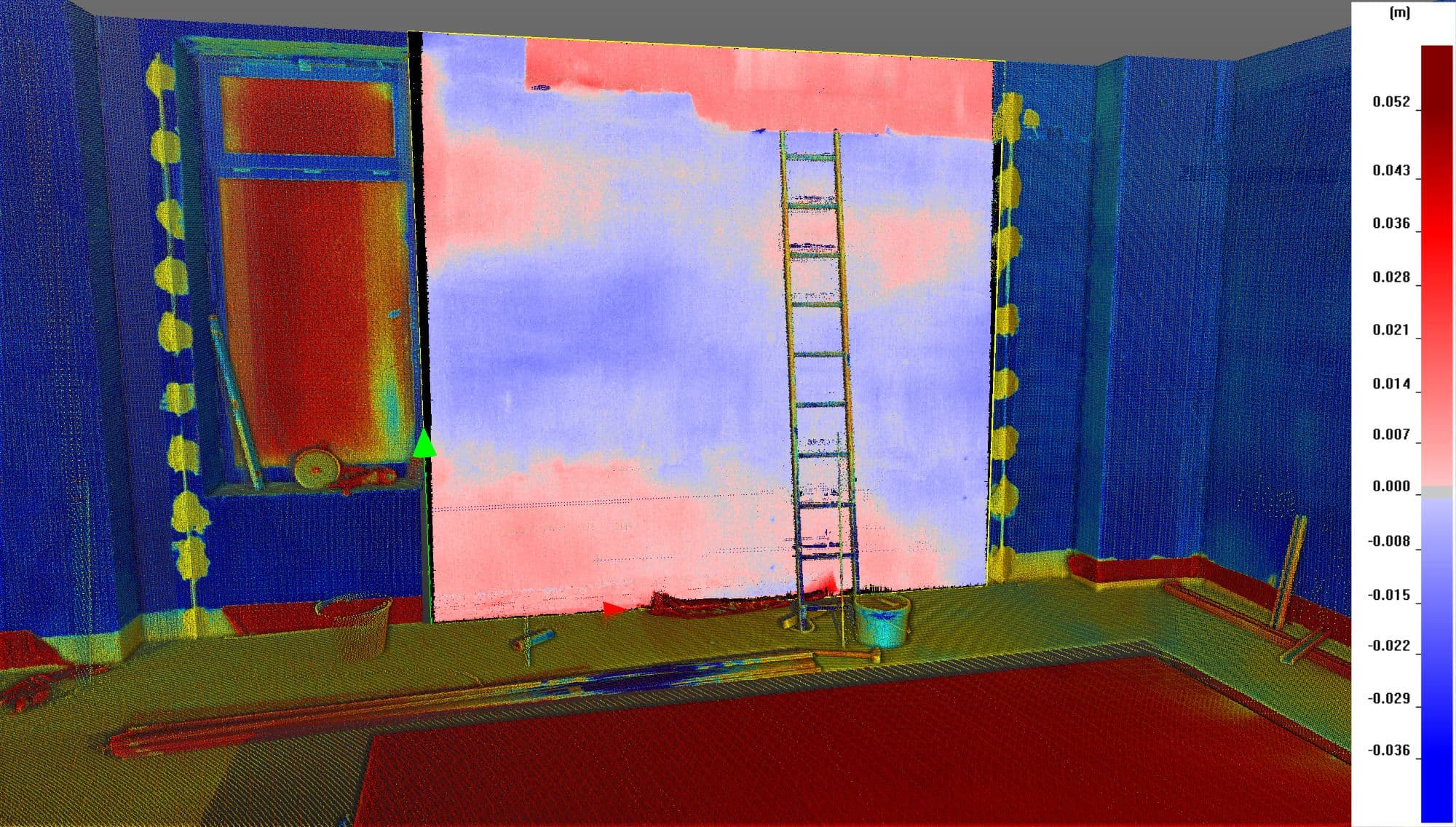

Determining deviations

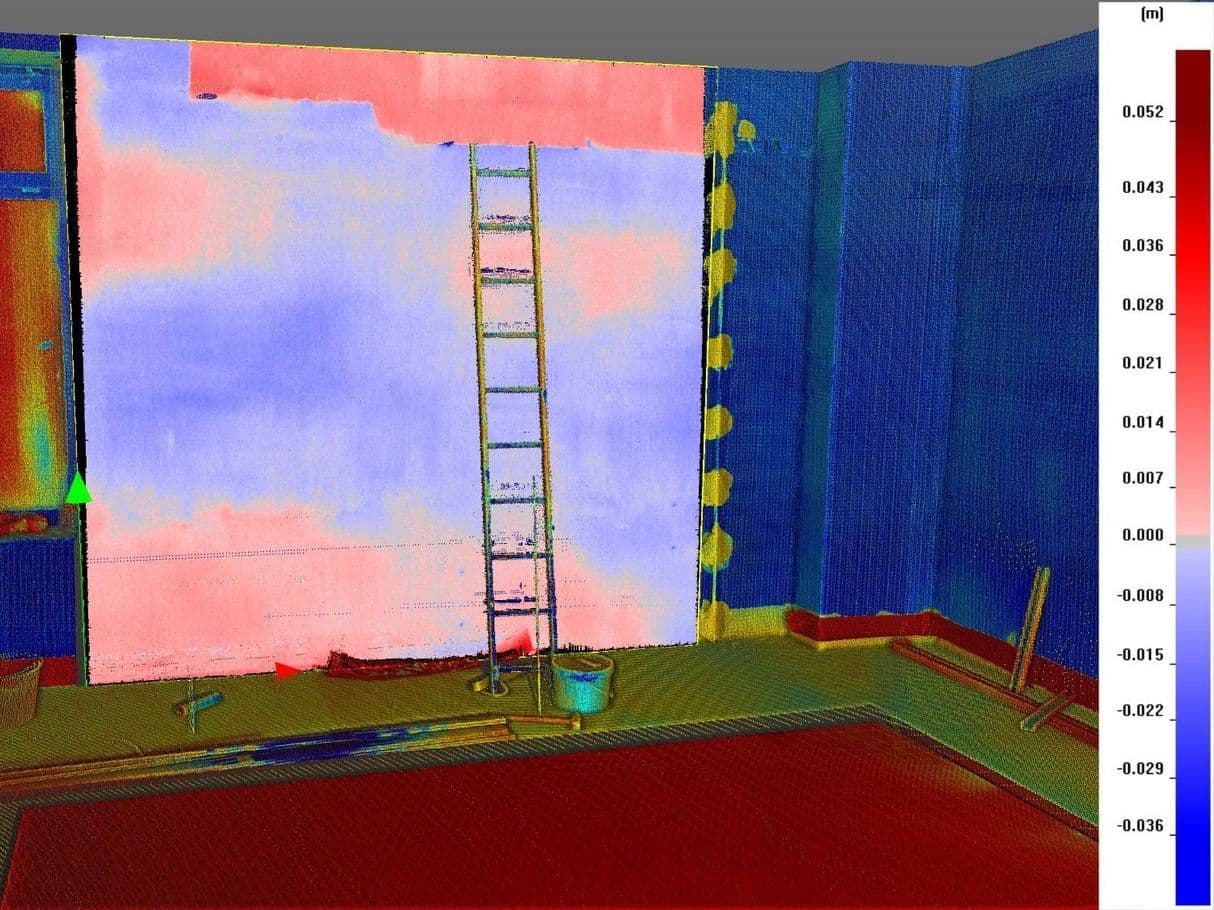

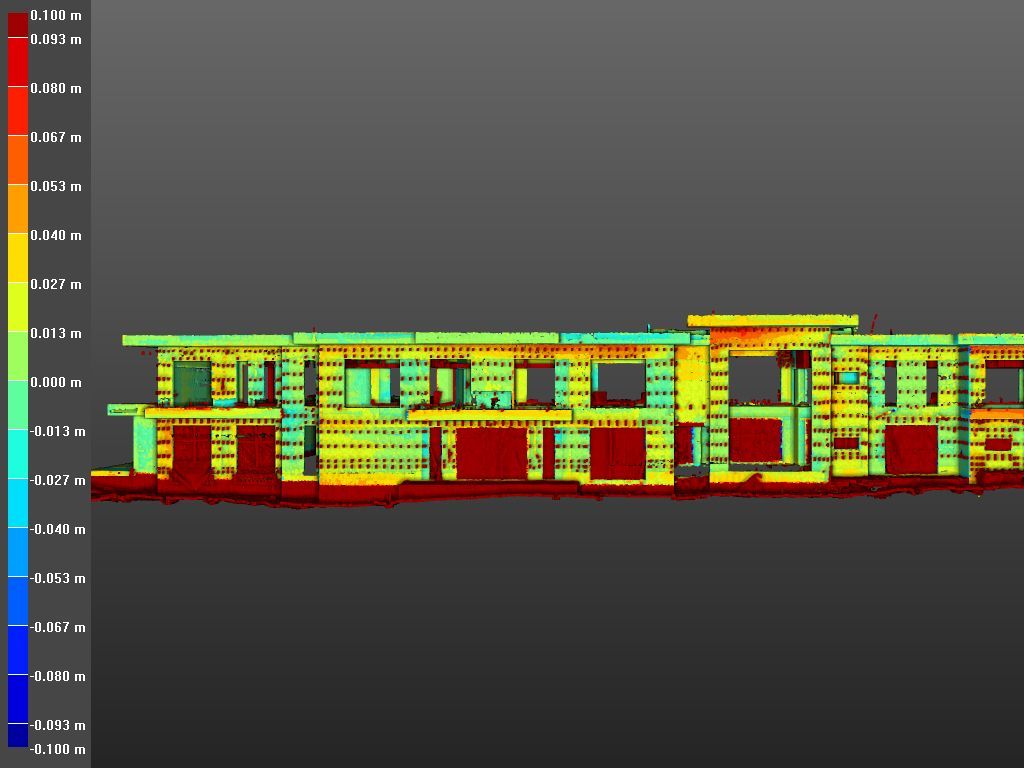

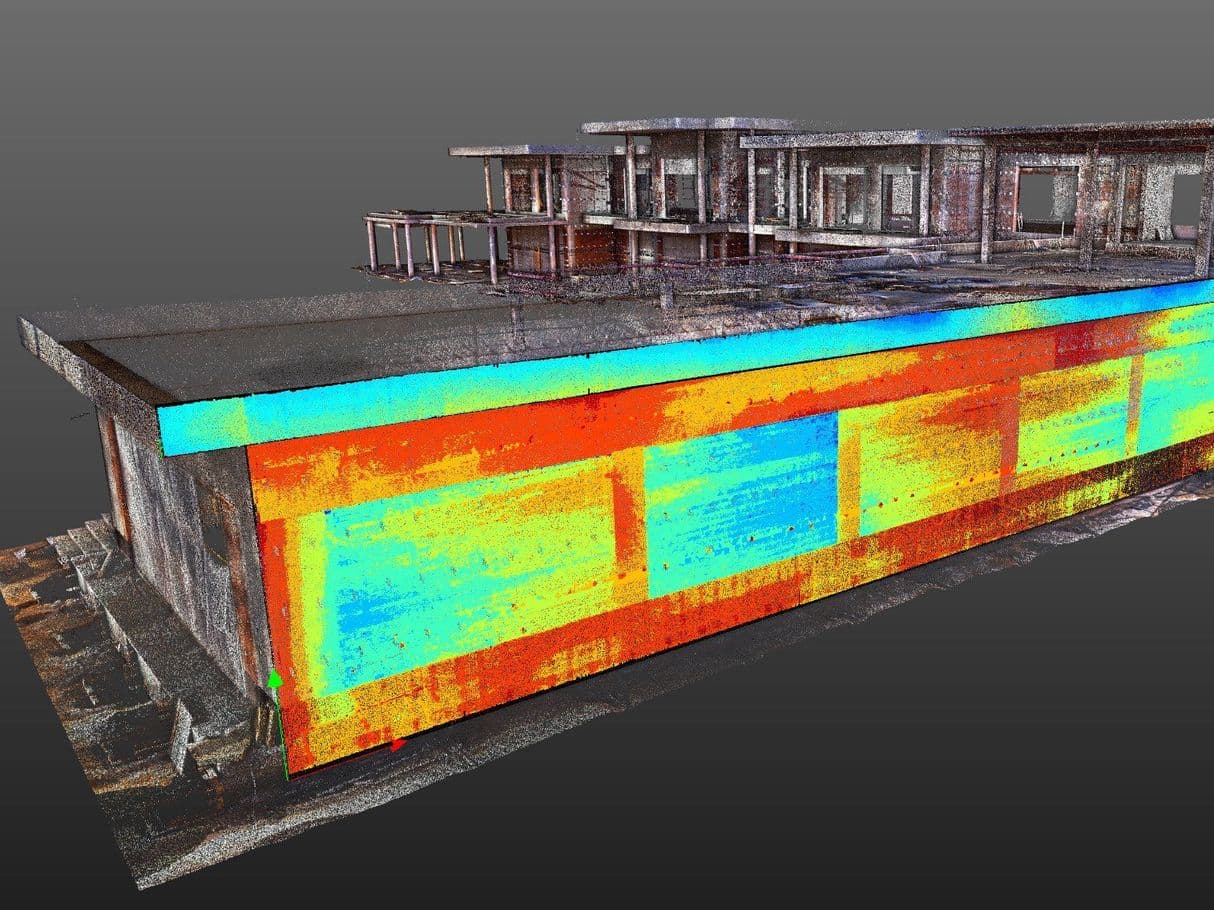

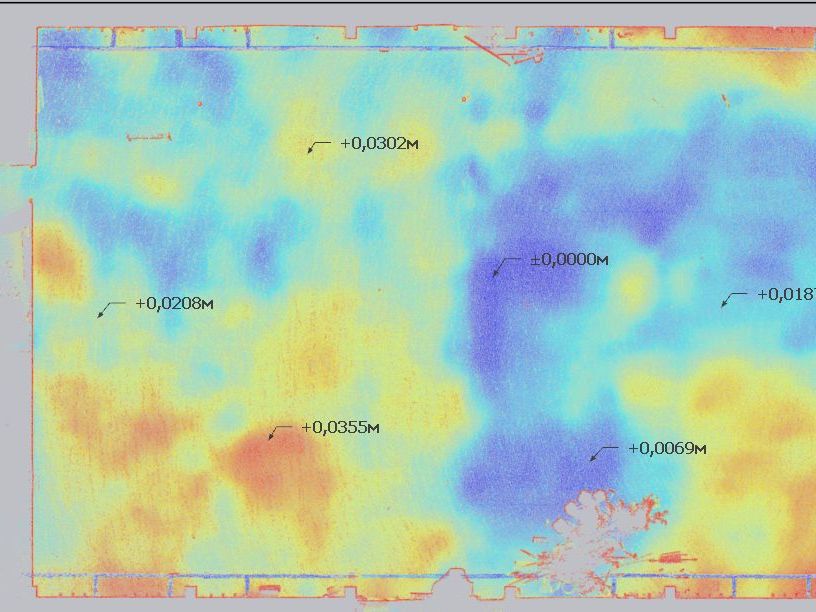

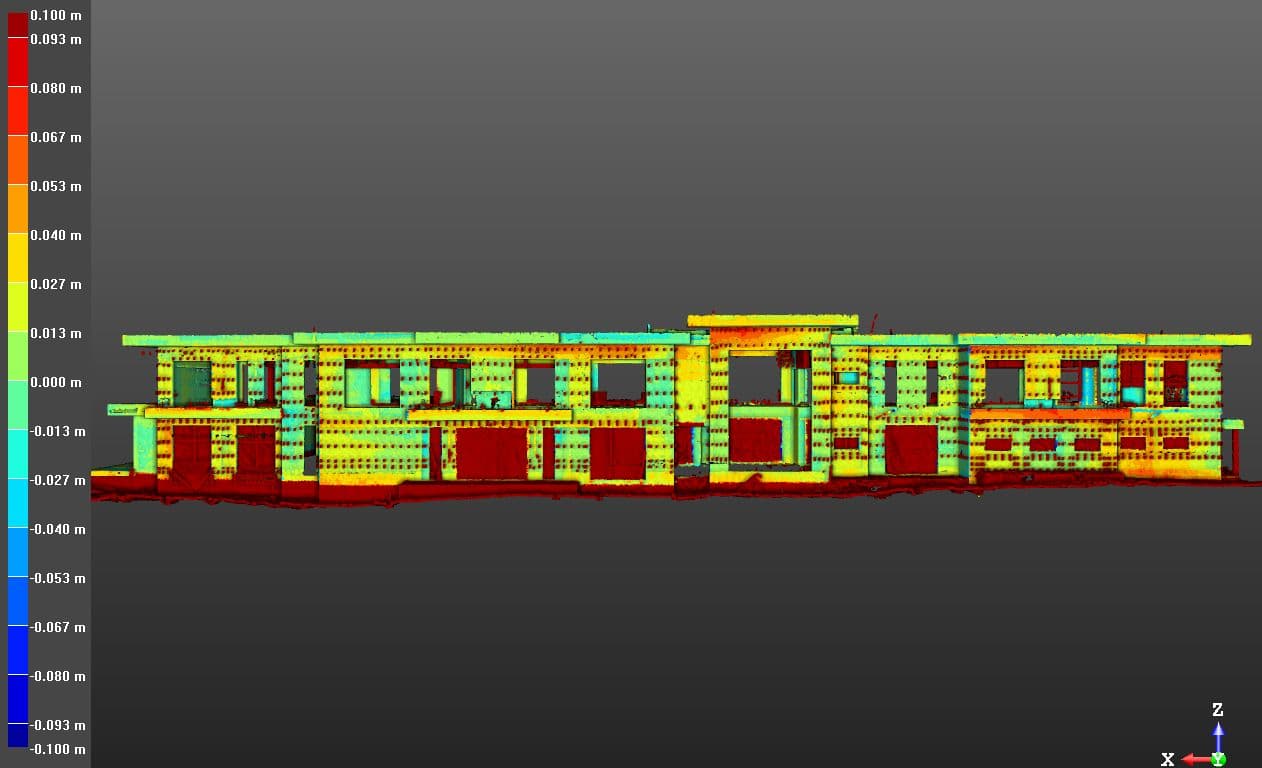

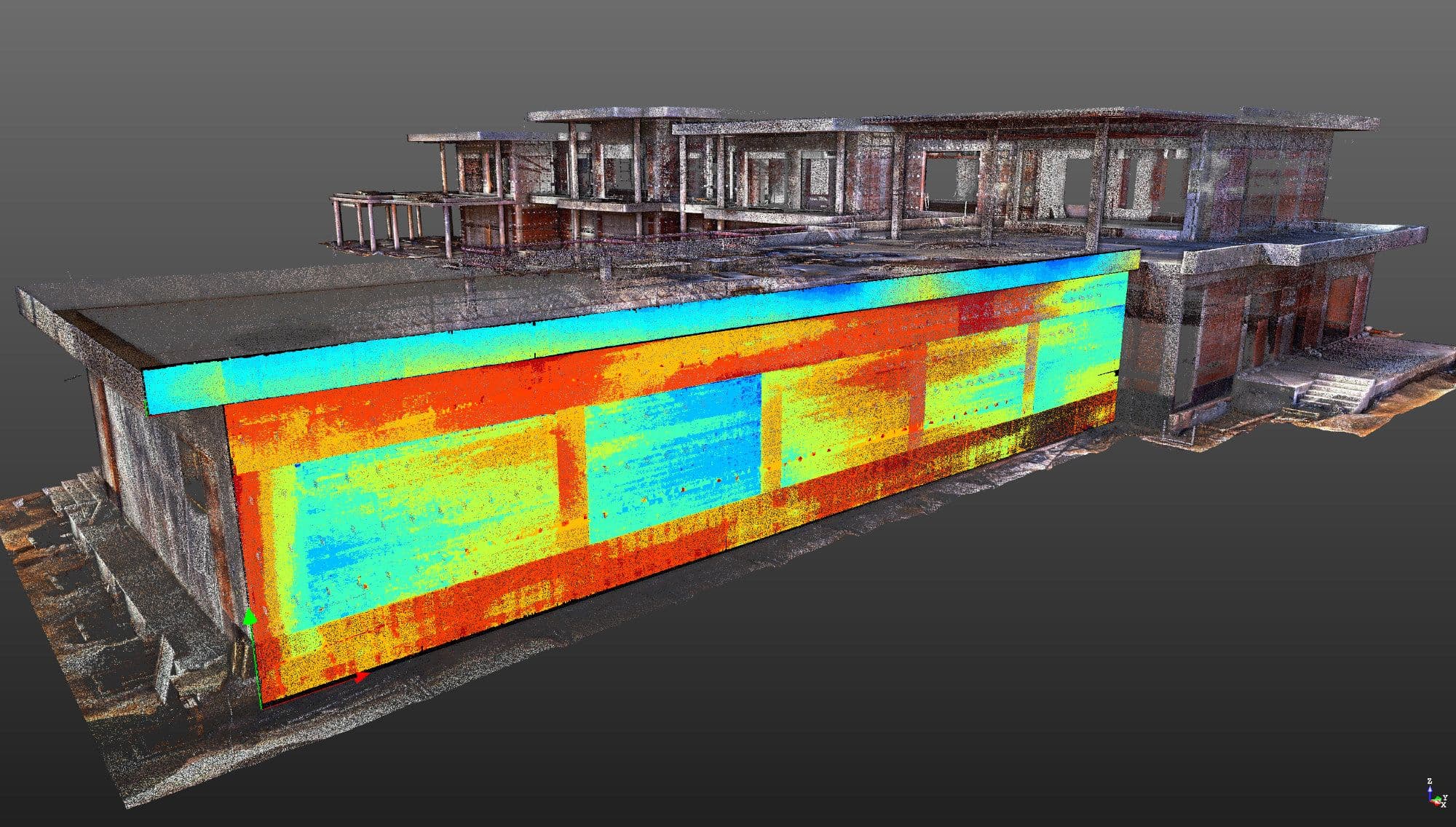

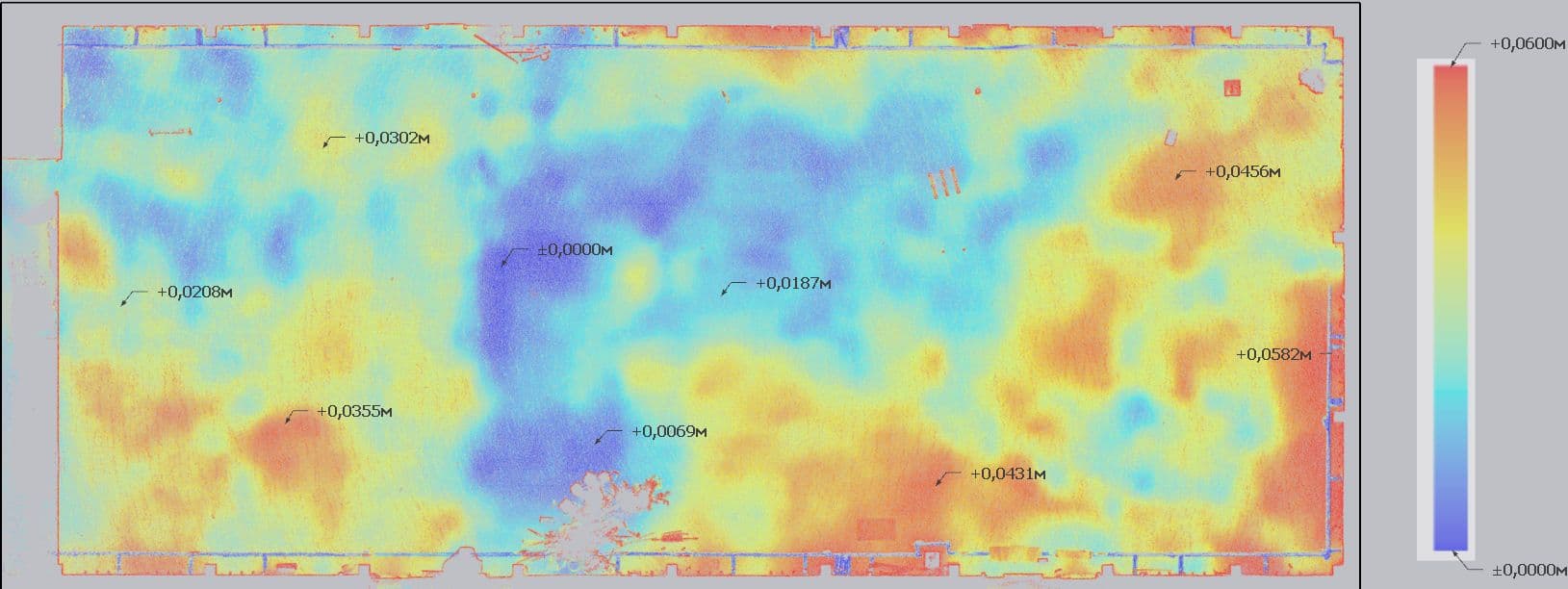

Determination of deviations in laser scanning is primarily carried out for construction control in order to eliminate errors and inaccuracies on time. Determining deviations allows clients to find areas with critical deviations, determine the degree of wear of parts, find out the curvature of walls and floors, calculate the volumes of rough and finishing materials, as well as compare clouds of points made at different periods of time.

Our specialists analyze and determine deviations from the design model or from certain surfaces. The deviation report contains a graphical deviation color map, an explanatory note with indicated tolerances, minimum and maximum deviations, and also files in DWG indicating the required peak points or deviation areas.

A deviation report is required for:

- determination of deviations in the actual state of the facility from the project 3D model

- determination of wall verticality

- determination of the floor horizontality

- determination of deviations during construction

- determination of soil excavation volumes over a certain period of time

- determination of wear and tear of mechanisms over a certain period of time

- filing a claim to the contractor because of the quality of construction work

- deciding on further actions

Our specialists analyze and determine deviations from the design model or from certain surfaces. The deviation report contains a graphical deviation color map, an explanatory note with indicated tolerances, minimum and maximum deviations, and also files in DWG indicating the required peak points or deviation areas.

- determination of deviations in the actual state of the facility from the project 3D model

- determination of wall verticality

- determination of the floor horizontality

- determination of deviations during construction

- determination of soil excavation volumes over a certain period of time

- determination of wear and tear of mechanisms over a certain period of time

- filing a claim to the contractor because of the quality of construction work

- deciding on further actions